Page navigation

Green Mobility

System component sizing

- Satisfying performance requirements (driving range, speed, acceleration, efficiency, etc)

- Minimizing energy consumption

- Maximize packaging efficiency

-

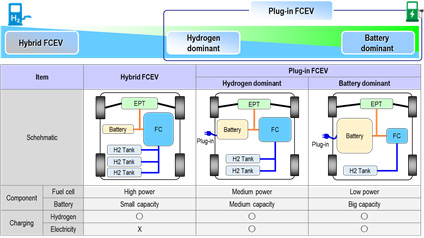

Powerplant system configuration examples for FCEV

-

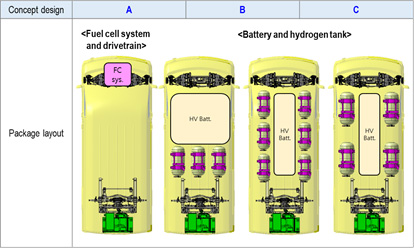

Packaging variants with various H2 tank and batteries

-

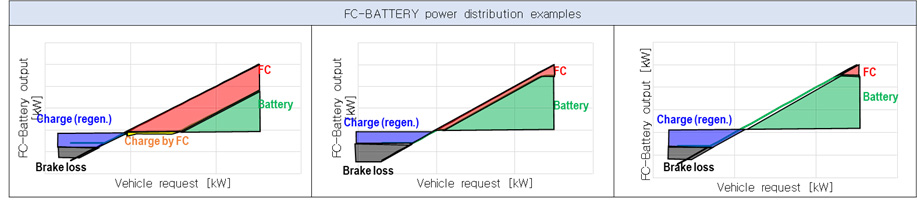

Powerplant system (FC and Battery) power distribution strategies example

Vehicle conversion procedure

1. Packaging Design

- FC/PE system

- FC/PE Cooling system

- H2 supply system

- Wire harness

- HVCU

- Energy flow display

Packing design validates layout feasibility of vehicle components.

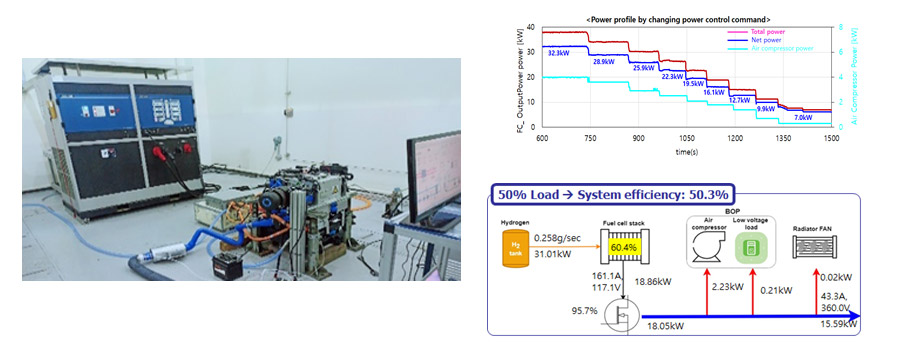

2. System Evaluation

-

FC system

- Performance

- Efficiency - HVCU control unit inspection test

- Battery/PE system

System level evaluation is executed to verify that each system satisfies the design specification.

3. Proto vehicle development

- Repainting

- Disassembly

-

Components

installation - Filling hydrogen

After confirmation of systems, proto vehicle is built.

4. Proto vehicle test

-

Calibration

- Driving control

- Power control -

Test

- Fuel economy test

- Drivability test

Vehicle level calibration is done and field test ensures the overall fulfillment of the vehicle development.

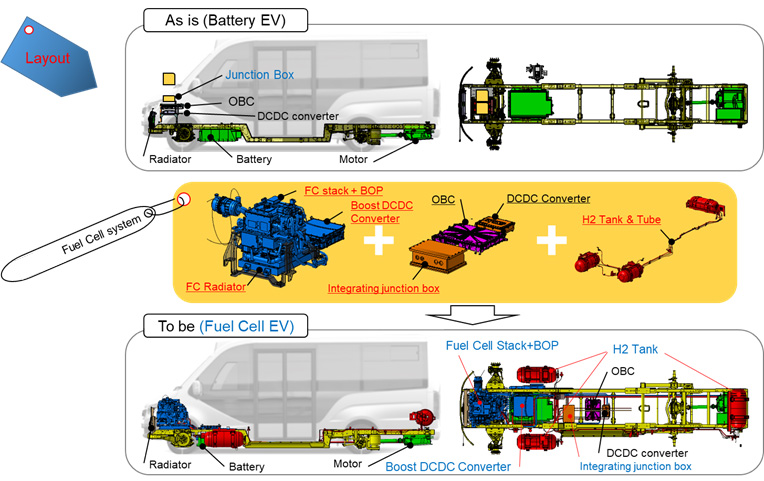

EV & FCEV platform development

EV > FCEV

Installation :

- Fuel cell system (FC stack & BOP)

- H2 tank

- Boost DC-DC converter

- Integrating junction box

- FC radiator

- etc

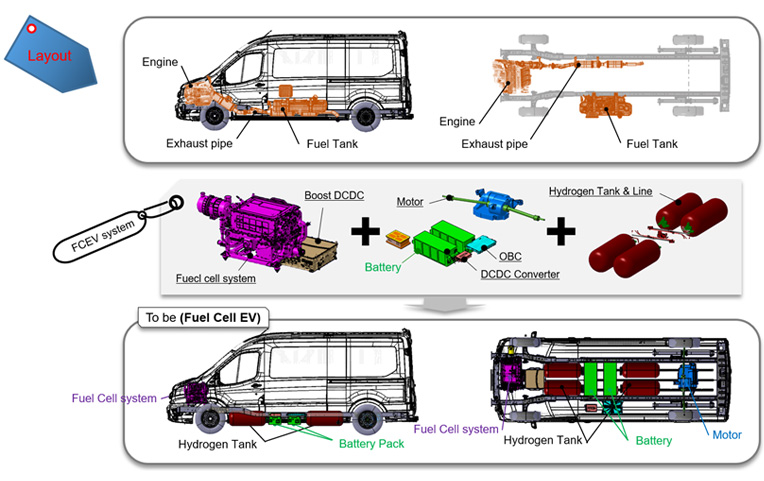

EV & FCEV platform development

ICEV > FCEV

Detachment :

- Engine

- Exhaust pipe

- Fuel tank

- Battery

- Motor

- Fuel cell system (FC stack & BOP)

- H2 tank

- Boost DC-DC converter

- Integrating junction box

- etc

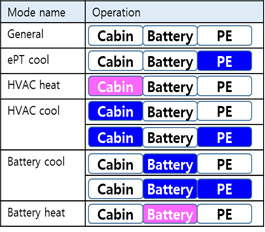

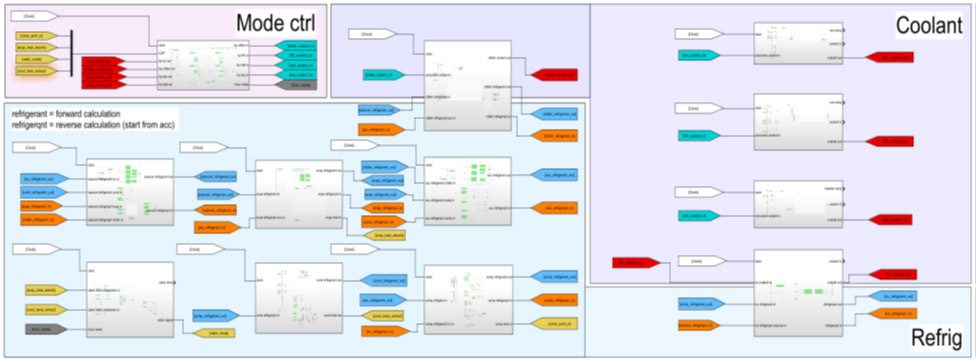

BEV Thermal management system

-

Define functions

-

System build and simulation

-

Rig test and validation

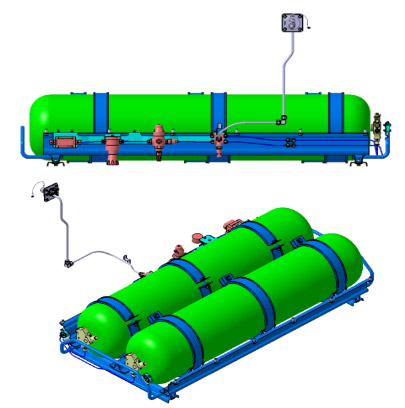

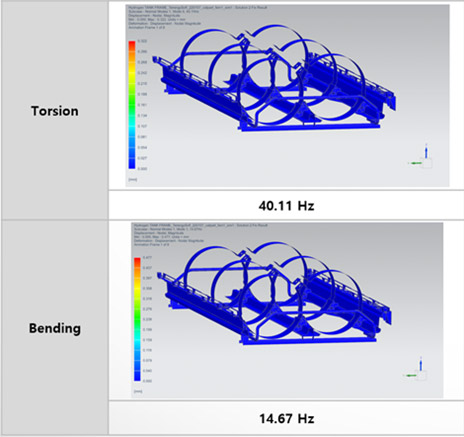

Hydrogen fuel supply system

-

System modeling

-

System strength simulation

-

Vehicle installation and test

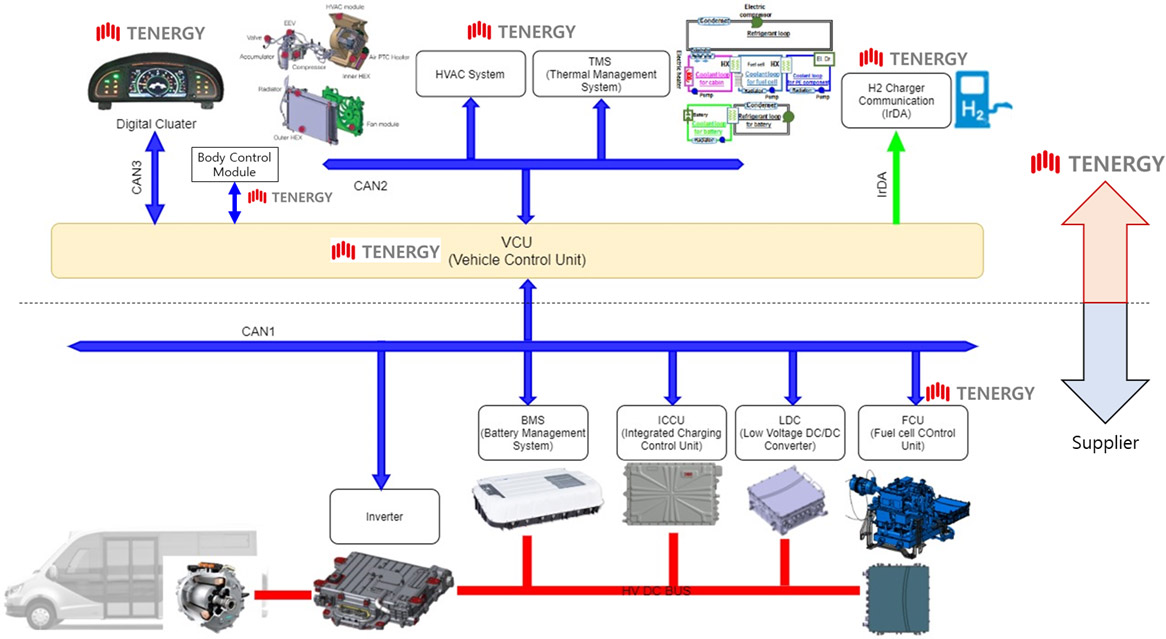

Vehicle control unit development

Controller for system integration (VCU, HVCU, HMU, TMS, FCU)

- Co-operative control (Traction control, regeneration, charging, TMS, …)

- Function limit considering system components

- Integrated E/E architecture

- Fail-safe

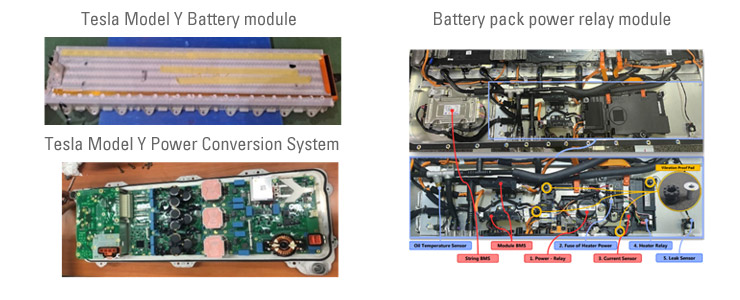

xEV Benchmarking

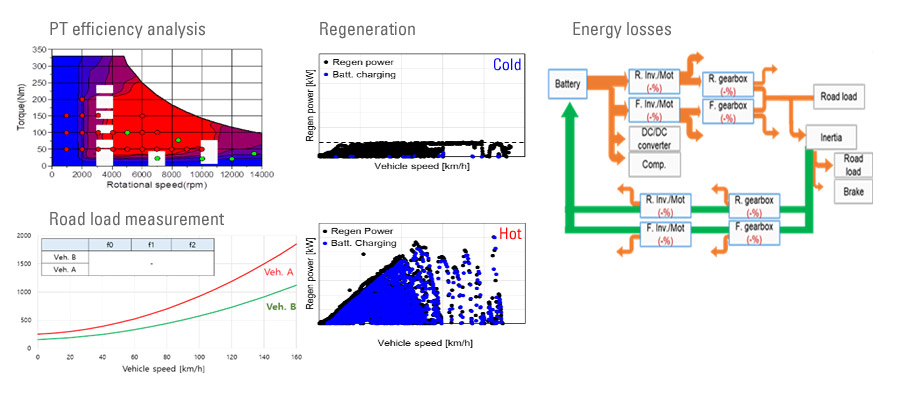

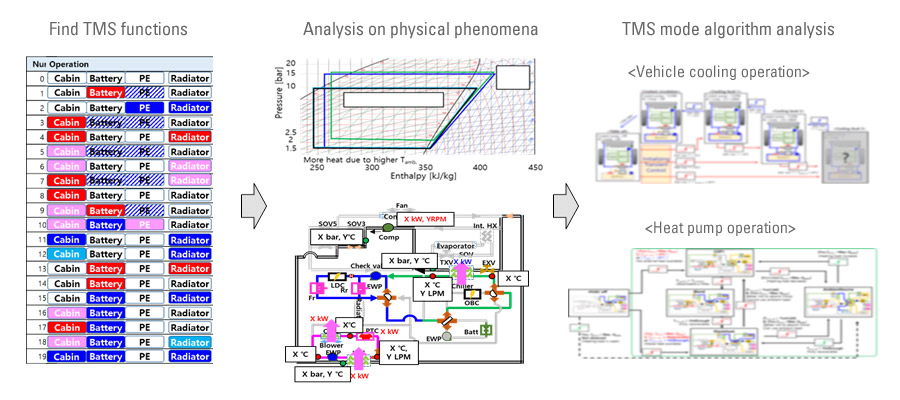

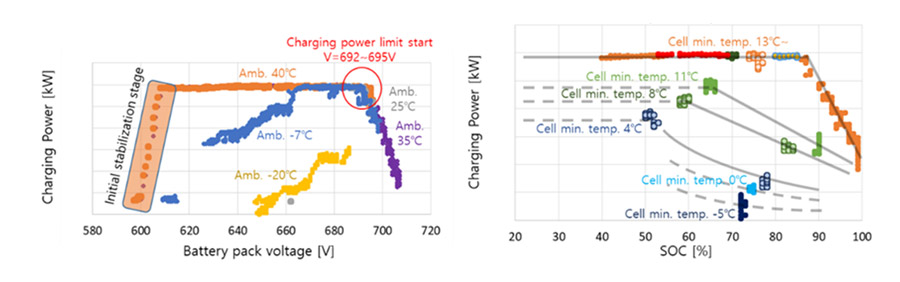

Vehicle electric economy, driving performance, TMS and charging strategies analysis

-

Vehicle electric economy analysis

-

Thermal management system analysis

-

Charging control map analysis

Benchmarked vehicles list

HEV/PHEV

- BMW 330e PHEV

- Audi A3 PHEV

- Lexus UX250h HEV

- KIA Sorento HEV

EV

- Tesla Model 3

- Tesla Model Y

- HMC Ioniq 5

- KIA EV 6

- Audi E-tron 55 quarttro

- BMW i3

- XiaoPeng P7 4WD

- BYD tang 600D EV

- BYD song pro EV

- GM Bolt

FCEV

- Nexo FCEV

- Elec-city FCEV bus

-

Benchmarking List (2019 ~ 2022)

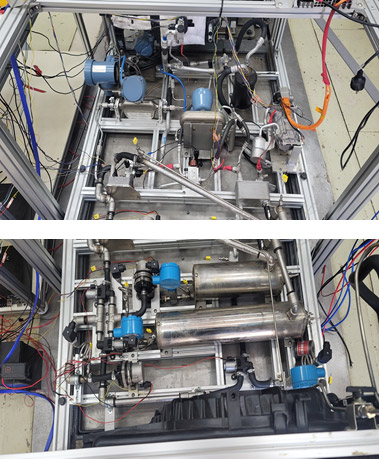

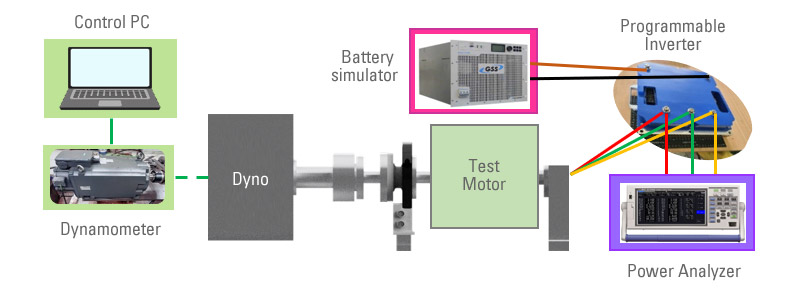

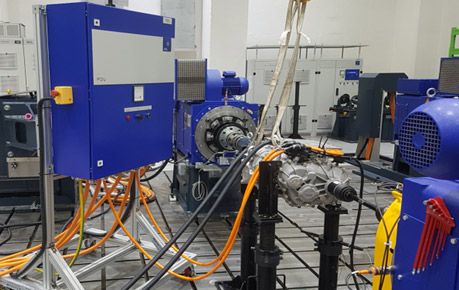

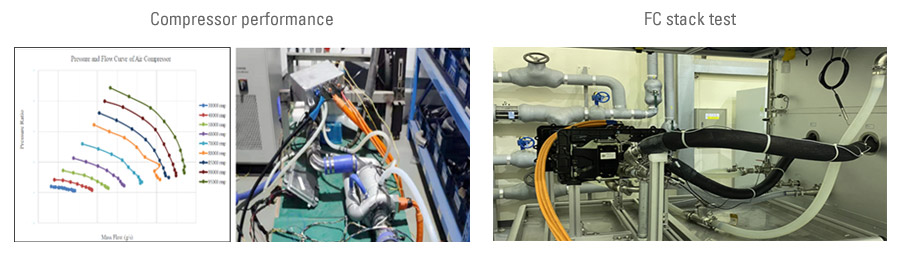

Electric Component Test

E-PT, high-voltage battery and fuel cell system/BOP test is available

-

Motor test

-

E-PT test

-

EV battery pack teardown and component analysis

-

FC component test

-

FC system test